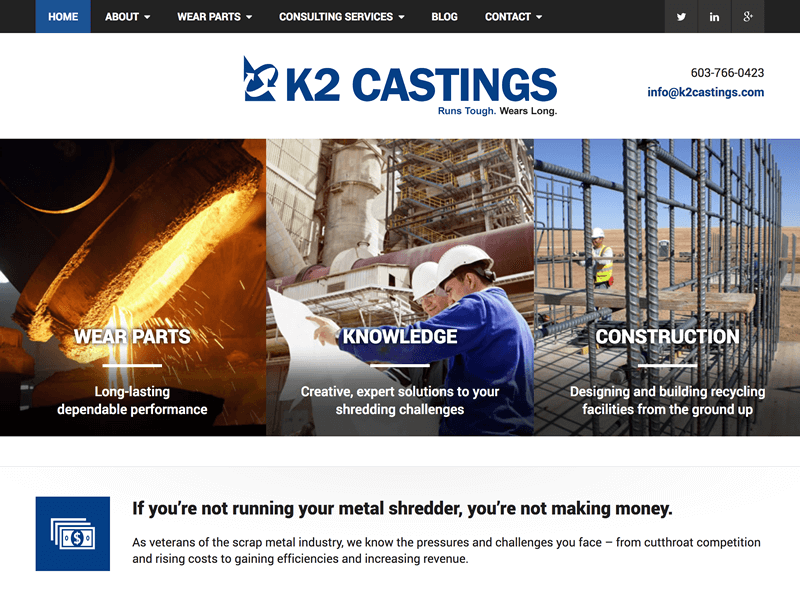

K2 Castings' experience and expertise goes far beyond simply delivering long-wearing cast wear parts. Our extensive knowledge base includes:

K2 Castings' experience and expertise goes far beyond simply delivering long-wearing cast wear parts. Our extensive knowledge base includes:

K2 Castings Stainless Steel

- Bringing multi-million dollar recycling facilities online from concept to completion.

- Installing shredding machines with your contractor or ours.

- Improving existing shredding facilities to deliver more tons and better recoveries.

- Developing and creating wear parts that help increase efficiencies, reduce machine downtime and lower costs.

- Helping operators buy or sell shredder machines.

We take an entrepreneurial and creative approach and work with you to solutions to your metal shredding challenges. No one is better equipped to serve you than K2 Castings. Casino night maine.

K2 Castings Inc. At ONE NEW HAMPSHIRE AVENUE SUITE PORTSMOUTH, NHNH 03801. Find their customers, contact information, and details on 237 shipments. R-3498-K2 You may need to scroll horizontally to view all table columns. Castings strong enough to handle severe loads are inherently heavy. Lifting these heavy lids/gates to gain access to sub-ground utilities has been an issue for maintenance crews.

K2 Castings wear parts are cast at an ISO 9001 foundry with strict attention to detail, quality and consistency. We've developed and tested our proprietary heat treat cycle and metallurgy for shredder parts that run tough and wear long.

K2 Castings Llc

Our material grades include:

K2 Castings

- Standard Manganese Steel – Cast from high-grade virgin manganese steel with proper hardening alloys.

- Mega Duty Manganese – As with our Standard Manganese Steel wear parts, Mega Duty Manganese parts are cast from high-grade materials but with additional hardening alloys and modified heat treatment.

- Low Alloy Steel – Alloy hammers deliver a higher wear rate and are ideal for operations that do not run a steady diet of autos and heavier scrap.

- Differential Heat Treat Alloy Steel – Quality metallurgy, strict attention to quality control, including ultrasonic testing, and a specialized heat treatment produce a high-performance hammer or wear part for many applications.